Customer relationship management is crucial in sheet metal manufacturing as it helps to build and maintain long-term relationships with customers. Here are some tips for developing strong customer relationships in sheet metal manufacturing:

Customer Relationship Management in Sheet Metal Manufacturing

May 12, 2023 9:00:00 AMDos and Don'ts to Welding

Apr 7, 2023 9:00:00 AMWelding is a common technique used in the manufacturing industry to create structures, products, and components.

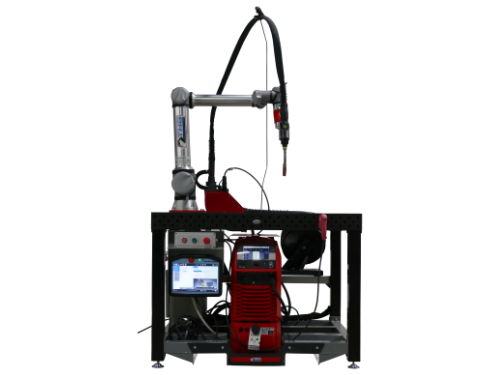

Robots, Can They Take Over the Welding Industry?

Sep 16, 2022 9:00:00 AMThese are one of the things that would always come up in conversations. Sure, it might sound possible with concern, but we understand where they are coming from when it’s been brought up. Because we feel it wouldn’t completely replace manual welding...

Safety First

Jun 27, 2022 9:06:55 AMAs you leave the work today, look up, down and all around, check out the beauty around you. Look at the sky, the different leaves in the trees, all birds in them. When you get home, watch your children and pay attention to how their eyes light up...

Common Welding Issues and How to Correct Them

Jan 28, 2022 9:00:00 AMWelding is a process where there are two or more pieces of metal or thermoplastics that are fastened together using heat and pressure. A variety of factors is involved with the process of welding, but the form and thickness of the material is the...

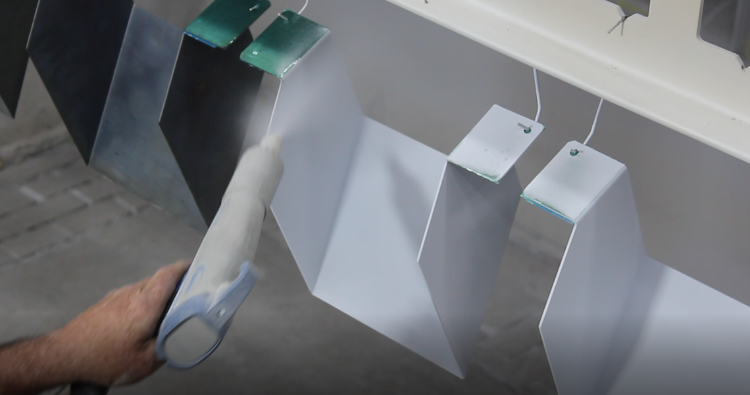

Everything You Should Know About Powder Coating Finishes

Dec 3, 2021 9:00:00 AMWHAT IS POWDER COATING?

Powder coating is a process of where a dry coating is in place as a metal finish on home products and industrial equipment. An Electrostatic process is involved with the dry powder that gets cured when heat is applied. A well...

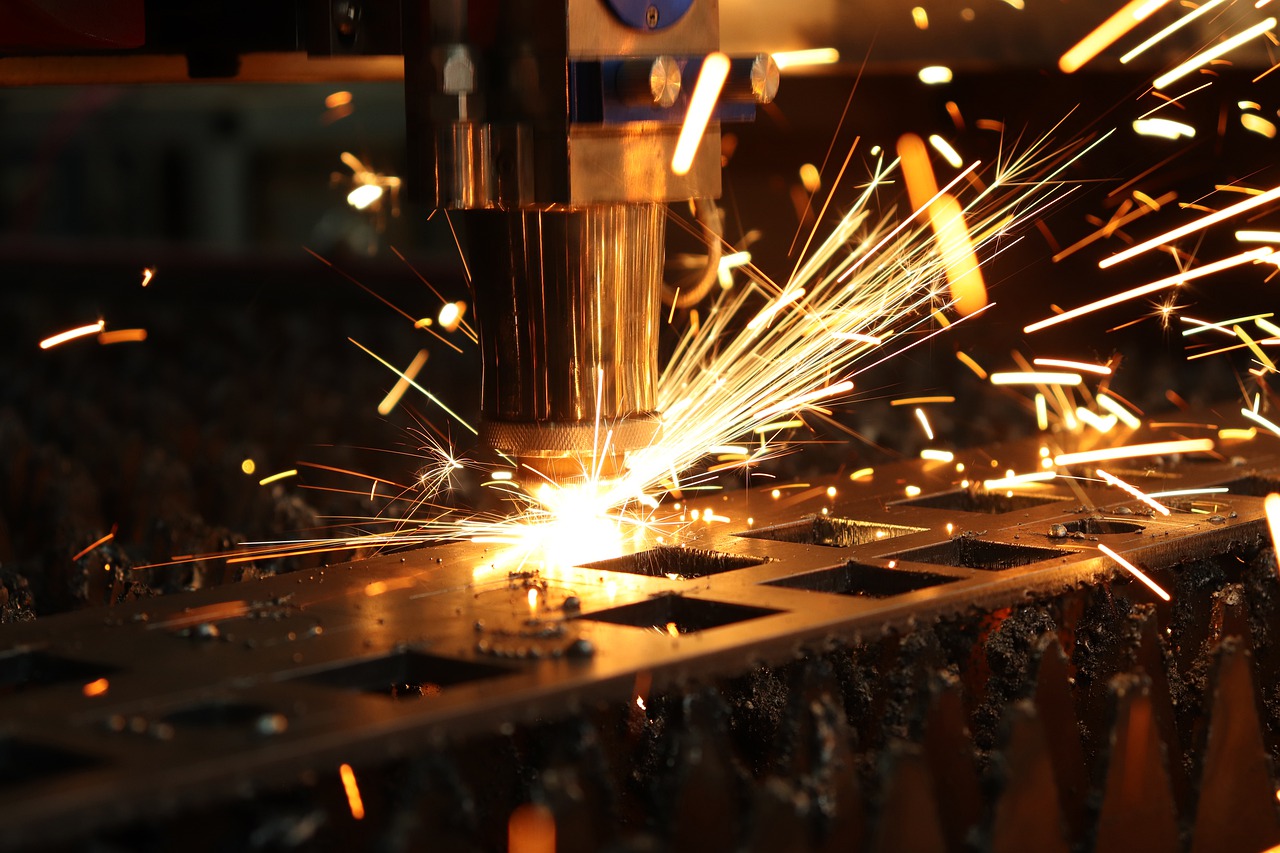

Is Fiber Laser Cutting The Proper Solution For Your Application?

Sep 20, 2021 9:00:00 AMWith today’s technologies, fiber laser systems have built their capabilities to be able to cut metals that are high quality and to accommodate precise geometries of different parts. These are challenging to other processes as well. When it involves...

Good To Know Tips When Welding Aluminum

May 25, 2021 7:16:57 AMWelding aluminum can be a challenge especially if you are just starting out. From having the perfect weld puddle to choosing the right power output of your weld, you might not get it your first time. With these tips it will get you on the right...

3 Ways to Correct Distortion after Welding

May 29, 2020 9:00:00 AMWeld distortion is the plight of every welder! If you’re are an engineer or a welder, you have likely encountered some shrinkage on your weld project. It’s at that moment after you have made the weld with a great-looking bead. After a while, you...

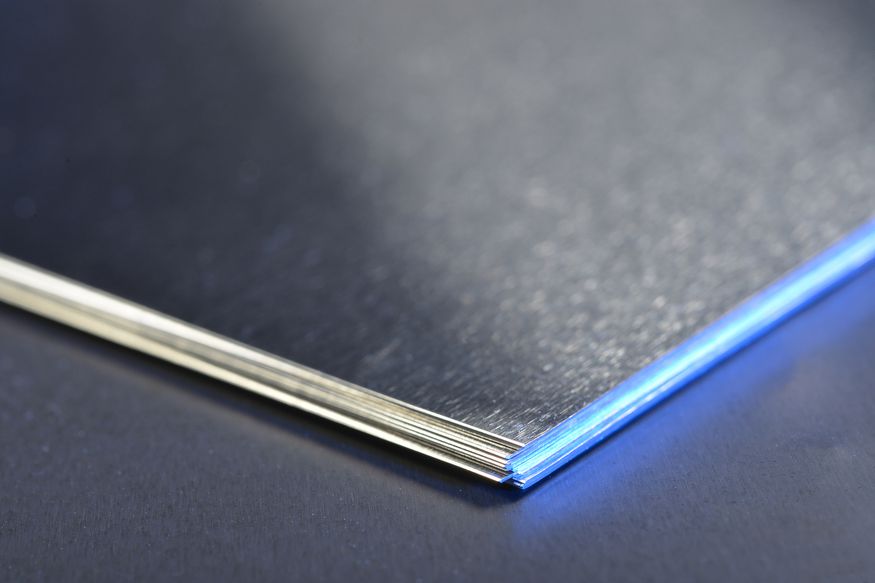

How Thin Can Sheet Metal Get?

May 22, 2020 9:00:00 AMMetal thickness is a critical factor in all manufacturing processes. It is a key determinant in almost all metal forming processes, from welding and fabrication to finishing.