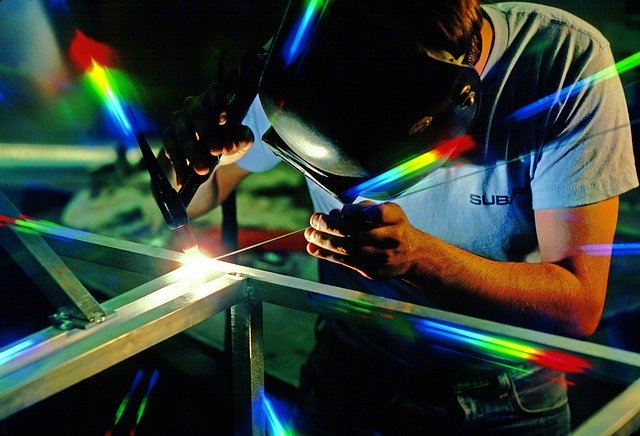

Welding is a common technique used in the manufacturing industry to create structures, products, and components.

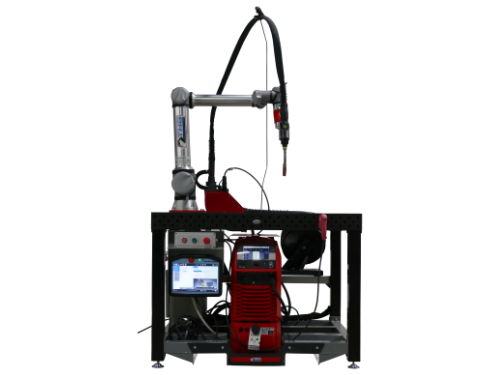

Robots, Can They Take Over the Welding Industry?

Sep 16, 2022 9:00:00 AMThese are one of the things that would always come up in conversations. Sure, it might sound possible with concern, but we understand where they are coming from when it’s been brought up. Because we feel it wouldn’t completely replace manual welding...

Common Welding Issues and How to Correct Them

Jan 28, 2022 9:00:00 AMWelding is a process where there are two or more pieces of metal or thermoplastics that are fastened together using heat and pressure. A variety of factors is involved with the process of welding, but the form and thickness of the material is the...

Good To Know Tips When Welding Aluminum

May 25, 2021 7:16:57 AMWelding aluminum can be a challenge especially if you are just starting out. From having the perfect weld puddle to choosing the right power output of your weld, you might not get it your first time. With these tips it will get you on the right...

3 Ways to Correct Distortion after Welding

May 29, 2020 9:00:00 AMWeld distortion is the plight of every welder! If you’re are an engineer or a welder, you have likely encountered some shrinkage on your weld project. It’s at that moment after you have made the weld with a great-looking bead. After a while, you...

What are Welding Defects & How Can You Avoid Them?

Apr 10, 2020 9:00:00 AMWhile welding is a simple process, metals are dynamic and tend to change during the welding process. Some metal pieces may expand rapidly when heated thus weakening the structure. A metal with a weakened structure may deform and develop cracks and...

Transferred vs. Non-Transferred Plasma Arc Welding

Mar 27, 2020 9:00:00 AMPlasma arc welding works by ionizing gases at high temperatures. Hot ionized gases are commonly referred to as plasma. Ionized gas that conducts electricity transfers an electric arc to the welding surface. The arc’s extreme heat welds two metal...

Advantages of Seam Welding

Mar 20, 2020 9:00:00 AMSeam welding is among the most popular welding processes for joining metals in a continuous weld. Highly preferred by welders, seam welding is practical for use on metals such as stainless steel, titanium, aluminum, and tungsten.

Common Welding Symbols: What Engineers Want You to Understand

Feb 7, 2020 9:00:00 AMUnderstanding the basic welding symbols can do wonders for your welds. They interconnect the designer with the welder. Any blueprint heavily peppers with welding symbols, and it’s vital to decipher them. Engineering and fabrication drawings may...

Overlap Welding: What is it?

Jan 24, 2020 9:00:00 AMWelding, like any other metal work process, is subject to numerous defects. Due to the complexity of the processes involved in welding, it’s possible to experience some few mishaps. Welding is an activity that involves not only the fire and metal...