Marine tank fabrication is a long process that involves lots of handling and precision. However, many think that it’s the normal fabrication process. If you want to run your boat or shop, it is mandatory to have some diesel. And with diesel, you...

How Marine Fuel Tanks and Sheet Metal Fabrication Coexist

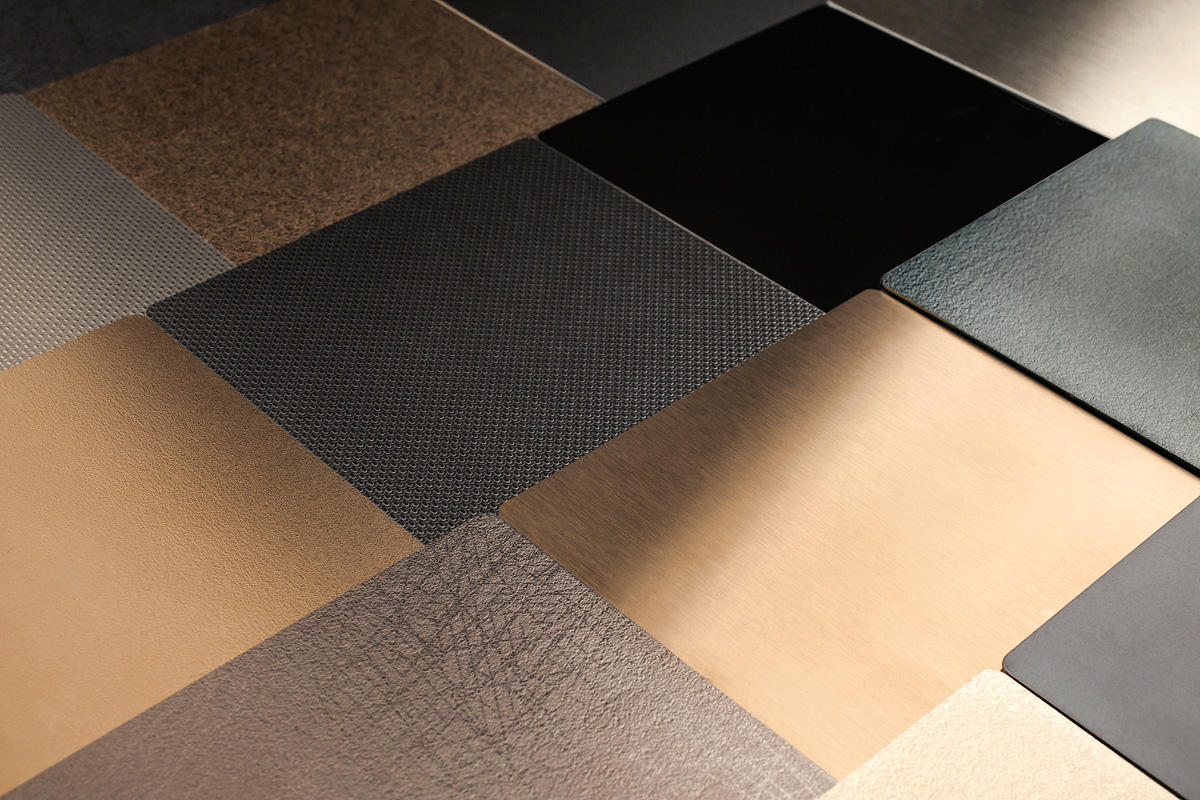

May 15, 2020 9:00:00 AMSteel or Stainless: What is the Most Durable Sheet Metal?

May 8, 2020 9:00:00 AMBoth steel (carbon steel) and stainless steel are the essential metal materials used in the majority of metal industries. To understand the various metalworking processes and parts, differentiating between the two is critical.

The Blackstone Fundamentals of Sheet Metal Design

May 1, 2020 9:00:00 AMSheet metal design is key to the production of quality products. For manufacturers to come up with desirable, quality-compliant metal tools, they ought to follow specific guidelines. Whether you are fabricating military equipment or automobile...

Number 2 vs Number 3 Metals: What You Need to Know

Apr 24, 2020 9:00:00 AMMetalworking is a naturally diverse niche. To understand metalworking, familiarizing with the different classifications and numbering is critical. All metals fall under a unified standard alloy numbering system (SAE). Both the SAE and the American...

The Stages of Preparing Sheet Metal for Finishing

Apr 17, 2020 9:00:00 AMThe process of converting sheet metal to a car chassis isn’t obvious. It’s a combination of engineering ingenuity and complex metalworking processes. From the coils you see hauling in trucks to the finished products, there are intricate fabrication...

What are Welding Defects & How Can You Avoid Them?

Apr 10, 2020 9:00:00 AMWhile welding is a simple process, metals are dynamic and tend to change during the welding process. Some metal pieces may expand rapidly when heated thus weakening the structure. A metal with a weakened structure may deform and develop cracks and...

5 Sheet Metal Enclosure Design Tips

Apr 3, 2020 9:00:00 AMYour next metal fabrication project is about to get real. Whether you want to design a metal enclosure for a sensitive machine or for simple storage cabinets, perfection is key. There are various practical difficulties to keep in mind while...

Transferred vs. Non-Transferred Plasma Arc Welding

Mar 27, 2020 9:00:00 AMPlasma arc welding works by ionizing gases at high temperatures. Hot ionized gases are commonly referred to as plasma. Ionized gas that conducts electricity transfers an electric arc to the welding surface. The arc’s extreme heat welds two metal...

Advantages of Seam Welding

Mar 20, 2020 9:00:00 AMSeam welding is among the most popular welding processes for joining metals in a continuous weld. Highly preferred by welders, seam welding is practical for use on metals such as stainless steel, titanium, aluminum, and tungsten.

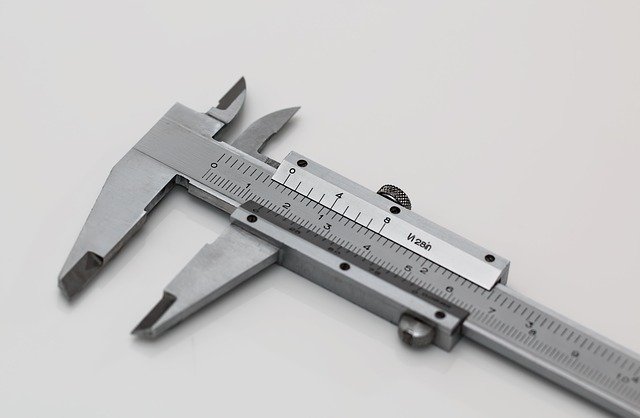

Ultimate Guide to Sheet Metal Thickness: What You Need to Know

Mar 13, 2020 9:00:00 AMUnderstanding the sheet metal theory is imperative to great welding and engineering experience. Since sheet metal contributes to the most significant percentage of metalworking processes, every welder should have a definite knowledge of this subject.