When you first begin working with sheet metal, you must understand bending basics. After all, bending metal is an art and a science. When manufacturing custom components, bending is required to change a part's geometry. Although the volume will remain the same, the metal's shape changes -- hence the importance of understanding sheet metal specifications.

When you first begin working with sheet metal, you must understand bending basics. After all, bending metal is an art and a science. When manufacturing custom components, bending is required to change a part's geometry. Although the volume will remain the same, the metal's shape changes -- hence the importance of understanding sheet metal specifications.

Sheet Metal Specifications: Understanding Bend Allowance

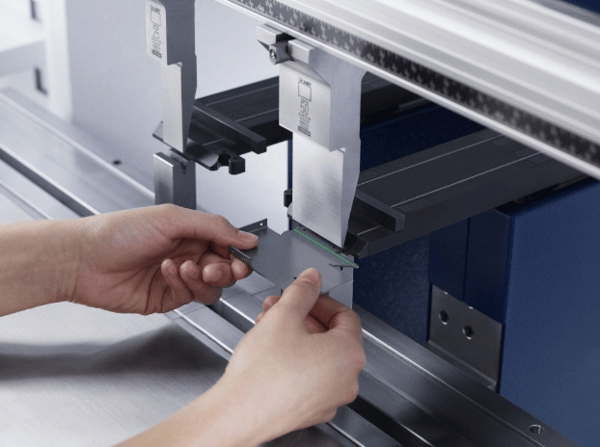

To fabricate parts, you must learn about various calculations and how those calculations will affect your finished product. When fabricating sheet metal enclosures, for instance, you will need to clamp and bend the metal. The key is understanding when to bend and how much. If you bend metal improperly, this can result in an improper fit.

Before bending any sheet metal, you need to consider both the layout and design of your flat pattern. The bend allowance takes into account the properties of your metal, including the thickness, the bend angle, the K-factor and the inside radius. This is not to be confused with your bend deduction -- which is the amount that your sheet metal will stretch when bent, measured from the bend's outside edges.

If you plan to bend metal regularly and to the right degree, you will require a sheet bending brake. The most common methods used are bottoming and air bending.

Can You Bend Sheet Metal Too Much?

When making a bend in sheet metal, you need to account for the minimum internal radius. If you bend sheet metal too tightly, for instance, this can compromise the structural integrity of the metal itself, while altering the final work's dimensions. When aiming to create a larger bend radius, folding will be required instead of bending.

Before you bend sheet metal, you need to consider two key things:

- The thickness of the sheet metal

- The hardness of the metal being used

This will help you determine whether or not specialized equipment is required. Once you have calculated your bend allowance, you will need to mark your lines, clamp your sheet metal and begin the bending process.

How much you bend will depend on your specific design and associated calculations. For more complicated designs, speak with a sheet metal fabricator who understands quality manufacturing practices and considers value engineering.

For More Assistance ...

When aiming to fabricate a quality, custom piece, it is often recommended that you contact your local shop. Based on their experience and equipment, even small quantities are affordable. The process will also be much more efficient. If you have a design you would like to discuss, please contact one of our skilled fabricators.