Welding, like any other metal work process, is subject to numerous defects. Due to the complexity of the processes involved in welding, it’s possible to experience some few mishaps. Welding is an activity that involves not only the fire and metal surfaces but also lots of technical aspects.

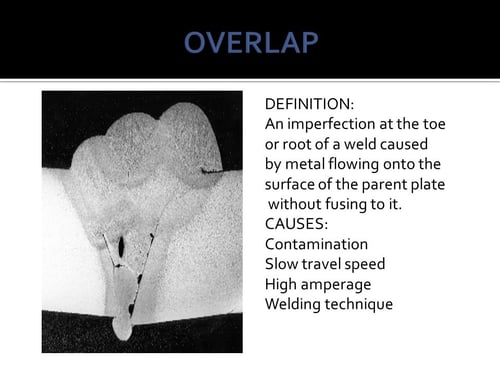

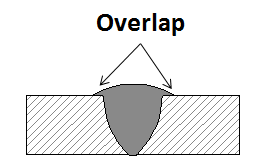

Overlap welding is the bulge of weld metal beyond the root. The overlap is a protrusion that occurs beyond the weld toe. Although overlap is more of a weld discontinuity, it’s still classified as a defect. Mostly, overlap occurs in butt and fillet welds.

When an overlap occurs, it means that the metal is not completely fused. Mostly, an overlap resembles a circle that extends into unnecessary places.

What Causes Overlap to Occur in Welding?

Various factors may cause the occurrence of an overlap. It occurs after the overflow of the weld pool on the weld metal surface. When the molten metal does not fuse with the base of the metal, it results in an overlap. This overlap might extend to form an angle less than 90-degrees.

Use of Excess Current

Using too much electric current causes an overlap. Too much current leads to over-melting of the weld material and a consequential overflow above the metal. Using excess current during welding might cause instances of overlap.

Excess Weld Metal

Having excess weld metal supplied is another cause of overlap. Excess weld metal occurs due to a low weld speed. The gravity on the molten material causes overlapping in fillet welds.

Wrong Electrode Angle

Also, using an electrode at the wrong angle contributes to an overlapping. The electrode is highly porous and using it in the incorrect angle results in nothing else rather than overlap. Also, large electrodes result in the occurrence of overlaps. Having an electrode larger than the metal size leads to an overlap.

How to Prevent Overlap in Welding

A proper welding technique is the ultimate solution to overlaps in welding. As evident, overlap occurs due to avoidable welding mistakes.

Using Small Electrodes

With large electrodes, you face a high possibility of having too much weld material applied to the surface. To avoid overlap, it’s advisable to use small electrodes. This is because small electrodes reduce the gap due to the application of less weld at each point. Small electrodes lessen the chance of excess materials and overlaps.

Using the Right Amount of Current

You should regulate your current depending on what you are working with. The levels of alternating or direct current should reflect the nature of the job at hand. The glowing or over-brightening of an electrode means you are using too much current. The ratio of an inch of electrode diameter to amperage should be 1:1000. This means that a quarter-inch diameter will take about 250 amps.

Better Welding Techniques

Welding is a technique that an individual should master. For example, slow welding results in the overlap of the weld material. To rectify this, you only need to consider your welding speed. Also, how you align your materials matter a lot. Depending on the specific welding technique, you need proper preparation and a good choice of materials.

Correcting Overlap in Welding

Majorly, and overlap is more of an excess disposition than a defect. Unlike other welding defects, it’s possible to fix a visible overlap by grinding the excess weld metal. Surface grinding smoothly at the base of the metal removes overlays.

The Bottom Line

It is essential to exercise as much precision as possible. By following the fight welding procedure, you can work out your way out of welding overlaps. For more tips on welding processes, contact us, and we will be willing to help.